Casing Hanger

Description: Casing hangers are the most important elements in your wellhead and are typically the primary driver in your wellhead selection.

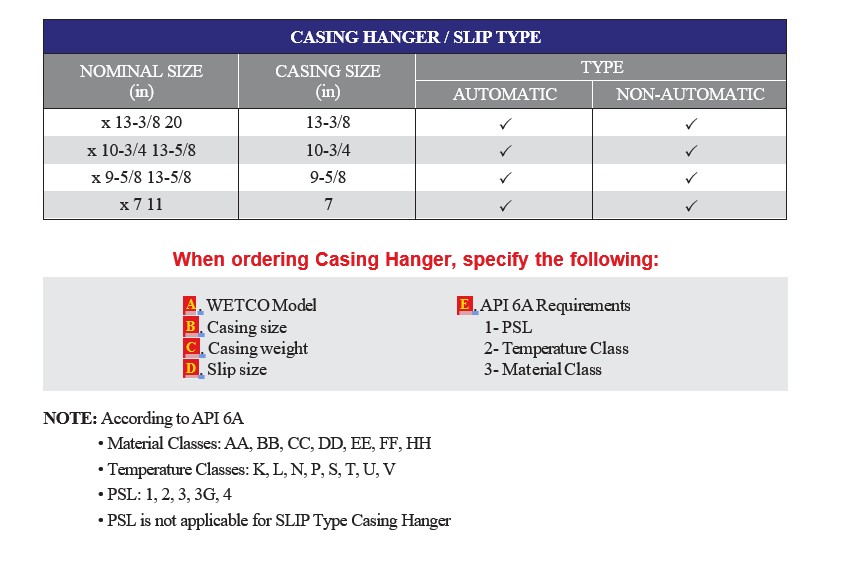

Slip-type casing hangers provide a method to transfer the weight or tension load of a casing string to a casing head or spool. Slip-type hangers are available in automatic-sealing and non-automatic-sealing varieties. Automatic hangers have seals which are energized by casing weight, while non-automatic hangers have seals which require means other than casing weight to be energized. Non-automatic hangers are typically used when insufficient casing load is available or when cementing back to the surface.

Critical criteria to select the appropriate casing hanger are:

- Automatic or manual sealing

- The load capacity

- Functions

- Provides for easy wraparound or split installation at any location on the casing

- Provides for suspension of the casing load from a casing head or

- Provides a means to center the casing string in the head or

- Provides an annular

Features and Benefits

- Fits all WETCO casing head housings and casing head

- Is designed to suspend typically encountered casing

- Provides automatic pack-off

- Has Interlocking slip

- Slips engage casing evenly, distributing casing load to the

Features and Benefits

- 10087 offers the same features as 42001

- Incorporates heavy-duty

- Allowing for ease of installation; has rugged, extensively tested,field-proven design.

Features and Benefits

- Fits all WETCO casing head housings and casing head spools

- Has a compression pack-off above the

- Provides interlocking slip

- Hangers can be lowered through blowout preventers and landed before or after cement has set.

- Isolates test pressure from hanging load, which allows for higher casing load/pressure combinations.

- Slips engage casing evenly, distributing casing load to the

Features and Benefits

- 42064 offers the same features as 42003

- Fits in spools witch has limitation on